The design of a stained glass window generally starts from a scaled handmade sketch or design, which is painted with watercolors. Watercolours have a similar intensity to the colored glass. In some cases a stained glass window can also be designed from a photograph, this is generally used to create a portrait or an image provided by the customer with this technique.

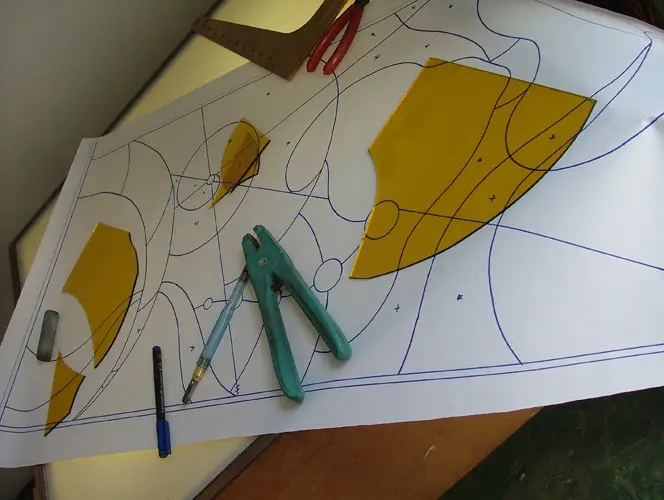

Once the design has been approved, it is then scaled up to full size using a plotter. Then we carefully apply the cut-lines to the design so that they correspond to changes in the glass mosaic as well as the structural requirements of this technique. It is important that these cut-lines work to enhance, rather than detract from the overall beauty of the final stained glass window. The cut-lines are just over a millimetre thick and represent where the lead will be used. We use the full range of different leads available on the market to maximise the beauty of the final window.

Using the highest quality coloured glass available, and sometimes even two different coloured glasses that will be layered to obtain the required colours, the glass is then hand cut, with utmost precision. To do this is we use diamond wheels to grind the glass until it fits perfectly into the cut-lines, helping ensure the final window meets the exact measurements.

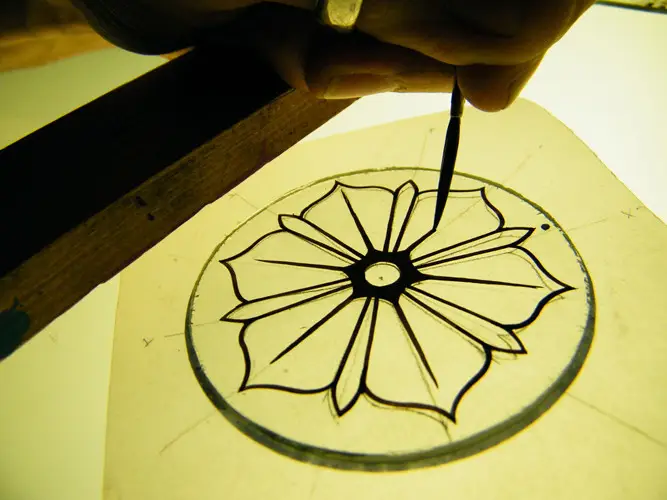

Painting the glass is undoubtedly the most difficult phase in the creation of a stained-glass window. The pieces are painted with Grisalia, a technique which mixes a dark pigment, made from oxides and finely ground glass, with a special medium that contains essential oils, Arabic gum, or water depending upon the painting techniques being used and the type of shading required.

Ad ogni fase ogni singolo pezzo di vetro verra’ cotto in forno a 650 °C dove la grisalia si vetrifichera’ sul vetro stesso in maniera irremovibile.

In alcuni casi verranno applicati anche degli smalti trasparenti di vari colori cotti poi in forno ad una temperatura leggermente più bassa di quella della grisaglia.

Per controllare la qualita’ della nostra pittura su vetro i vetri potranno essere disposti nel giusto ordine su un tavolo luminoso o attaccati su una lastra di vetro trasparente per ammirarne l’intensità delle ombreggiature.

The lead strips have an ‘H’-shaped cross section. The lead is particularly malleable and is curved around the glass mosaic. The pieces are are then soldered together to hold the glass in position, ready for the cementing stage.

The window is then cemented with a special lead cement made by us, to our special blend of chalk, linseed oil, a binding agent and a black pigment that helps darken the lead for polishing. The cement fills the spaces between the lead and the glass and hardens rendering the window weatherproof, for approximately 100 years. The window is then cleaned and brushed and the lead hand polished to perfection. The finished window is then ready to be installed. Many stained glass windows last over 100 years, after which the lead can be easily replaced and the window re-cemented, extending its life still further.

| Course | Design | Cut lines | Glass cutting | Painting | Leading | Soldering | Cementing and finishing |

|---|---|---|---|---|---|---|---|

| Leading | |||||||

| Lead with grisaglia | |||||||

| Painting | |||||||

| Tiffany |